Hgg Beam Cutting Machine

Mac-Tech carries a number of structural steel cutting machines, robotic plasma cutters, beam drilling, and beam coping machines suitable for businesses in the metal fabrication industry. Some of the structural steel cutting machines, beam coping machines, and CNC beam drilling machines we carry may do much more, as is the case with the PCR41 and PCR42; however, you can rest assured that each of the pieces of structural steel fabrication machinery we have listed here will meet your structural beam coping or drilling needs.

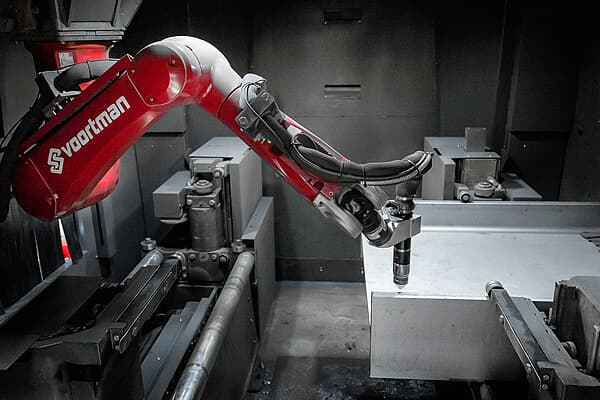

The most versatile application process in most cases is coping and the machine capable of being as close to a �all-in-one� solution as possible is a robotic plasma processor. Rat holes, seismic structural design connections like jay-allan and �dog bone� cuts, copes at the lead or trail end of a product, block outs, holes in any size, weld preparations, marking on all sides � all are possible to process with a plasma unit and a robot.